© 2018 Zhangjiagang Hengyu Machinery Co.,LTD All rights reserved. Designed by iwonder.cn Site Map

Email: info@hengyu-machinery.com

Email: info@hengyu-machinery.com

Capacity: 8000BPH

Material: SUS304/316

Function: Washing filling capping

Introduction

1.This glass bottle beer filling machine is used for filling, washing and sealing of beer drinks in glass bottles with metal crown caps or easy-open caps.

2. It used sensor as speed regulator so that clients can easily adjust machine to meet different power demand.

3. It adopts equivalent pressure filling principle and spring valve to control the quality of beverage.

4. All portions, such as feeding valve, which contact with material directly are made of 304 stainless steel or 316L material to meet the demand of food hygiene.

5. This machine employs international advanced technology with scientific design, nice appearance, complete functions, easy maintenance and high automation. It is a top priority for small and medium sized beer manufacturers and companies.

Technical parameter

Model | BPGF 12/6 | BPGF 18/6 | BPGF 24/6 | BPGF 32/8 | BPGF 40/10 | BPGF 50/12 | BPGF 60/15 |

Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 |

Capping heads | 6 | 6 | 6 | 8 | 10 | 12 | 15 |

Capacity(BPH) | 2000 | 3500 | 5000 | 8000 | 12000 | 16000 | 20000 |

Power(kw) | 2.2 | 3.5 | 4.5 | 6 | 7.5 | 9.5 | 11.2 |

Dimension(mm) | 2400*1600 *2500 | 2600*1920 *2550 | 3100*2300 *2800 | 3800*2500 *2900 | 4600*2800 *2900 | 5450*3300 *2900 | 6500*4500 *2900 |

Weight(kg) | 2500 | 3500 | 4500 | 5600 | 8500 | 9800 | 12800 |

The Beer Bottling Line adopts the advanced international technology .The design is scientific and reasonable ,appearance is beautiful ,operation and maintenance are convenient ,and it is with high degree of automatization. It is the good machine for choosing by the drinking filling factory.

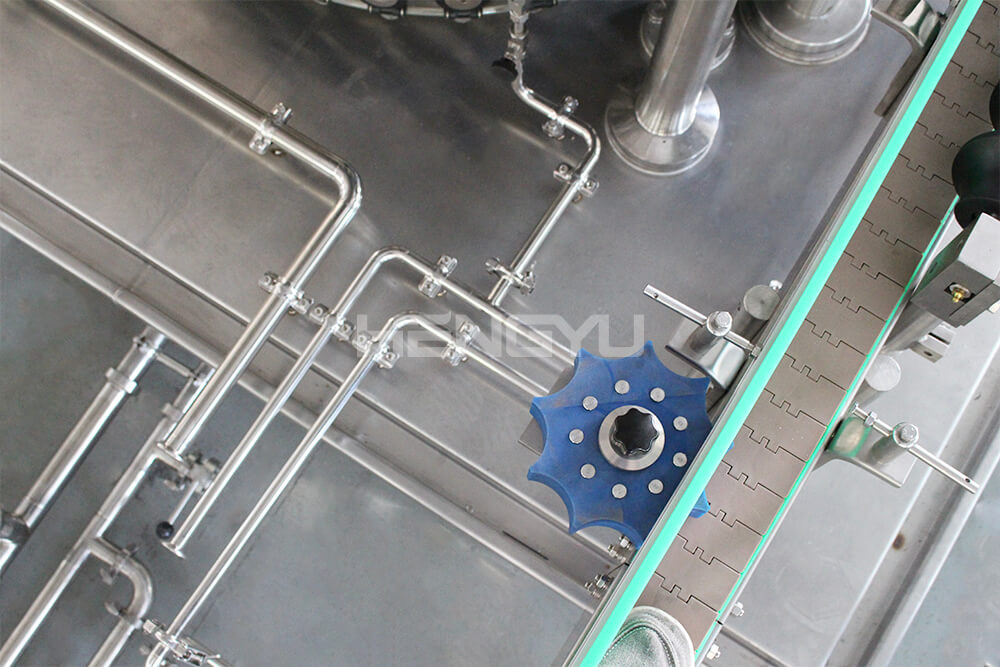

Washing Parts.

Rotatory bottle-rinsing machine has the functions of not opening the valve and rinsing without bottle, which is working from bottle entrance,bottle transportation,bottle clipping,bottle turning around with synchronously rinsing inside of the bottle to water-dropping and exit have the functions of not opening the valve and rinsing without bottles.

Filling Parts.

The Automatic Glass Bottle Beer Filling Machine adopts the advanced international technology .The design is scientific and reasonable ,appearance is beautiful ,operation and maintenance are convenient ,and it is with high degree of automatic. It is the good machine for choosing by the drinking filling factory.

Filling Heads.

Adopting the way of filling by holding the necks of the bottle, plus the function of pre-cover of the centralizing cover with high precise centralization,which ensure the right seating of mouth of the bottle and filling valve,with low liquid loss.

This series of Automatic Glass Bottle Beer Filling Machine can meet the filling-sealing requirements of different sealing manners for crown cap /screw cap or others.

Adopting crowning the caps with magnetic force,which passes the torque with powerful and constant magnet,and the torque can be adjusted to meet the need of many kind of caps.

Flat Conveyor.

<1>Energy saving. High efficient. Adapt to customer factory layout

<2> Special lubrication system, keep products clean, health, safety

<3>Extended service life

<4>Electric eyes design keep whole line running safety and quickly

<5>Overload protection mechanism to effectively ensure the safety of the machine

Water treatment system.

1 Raw water tank + Raw water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

1/Stainless steel high pressure film shell

2/All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3/Online type pressure auto self-protection device

4/Online type electricity indicator (with stable compensation)

5/System safe protecting and alarm system

6/System frame

1. suitable beverage types: Cola and lemon.

2. mixing ratio range: 3:1 - 6:1

3. CO2 content: 4 times

4. volume: CO2 consumption of about 4 M3/h

5. CO2 supply pressure: 0.8-1 Mpa

6. CO2 Purity: 99.9%

7. consumption of ethylene glycol solution: water=30M3/h

8. ethylene glycol solution pressure: 1.0Mpa

9. ethylene glycol solution inlet temperature: -2 C.

mpty Bottle Feeding Table.

The table is specially designed for the bottle up-loader and bottle collect ,or you also can prepare them yourself .

Material :Stainless steel SUS304.

Conveyor.

1.Side panel: 304 stainless steel

2.Supporting leg: 304 stainless steel pressing structure

3.Bearing housing: 304 stainless steel cage

4.With domestic brand motor speed adjustable

5.It should be designed by your factory layout

1/Mainly for cooling and sterilization

2/The main parts of the machine are made of stainless steel, the top is designed to be openable for easy maintenance and observation

3/Nozzles are manufactured using U.S. technology and spray water evenly

4/Conveyor belt adopts Rexnor technology, flat surface with small wear

5/Smooth and reliable operation with low energy consumption

1/Heat shrink sleeve labeling machine

2/OPP Hot melt labeling machine<in picture>

3/PVC label stick labeling machine

It adopts double driving structure which is a new and advanced driving device for the thermal shrink sleeve machine, that is, four-wheel driving, self-centering and balanced pressure of four wheels. It can achieve the good effect of transmission of labels smoothly, stably and rapidly.

1/PE film shrink wrapping machine<in picture>

2/Half-tray shrink wrapping machine

3/Carton box packaging machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.

Company Introduction

Zhangjiagang Hengyu Beverage Company is a professional beverage packaging machinery manu-facturer, which is located in the national civilized typical city - Zhangjiagang City, east of Shanghai,the west of Nanjing, North pillow Yangtze River, the traffic is very convenient. We have more than 20000 square meters of factory area. Companies to many years of researchresults and production experience as the basis, widely absorb and digest the advantages of thesame industry at home and abroad, and one after another from Germany, Italy, the introductionof a full set of the latest beverage packaging machinery technology.To Provide high quality bever-age equipment for domestic and international customers.The company has several series of inde-pendent research and development products, has obtained the national patent. As the senior beverage machine manufacturer, the working environment is elegant, has the per-fect modern office condition, has the specialized sales department, the research and developmentdepartment, the technical department.The workshop is spacious and bright, with complete equip-ment, and has more than 10 years of professional background operation, technical personnel.We adhering to the innovative, mutually beneficial win-win principle, and strive to provide custom-ers with the most suitable equipment products, customers become safe and efficient productionof the best choice!

Our service

1)The machines' quality that we sold will be guaranteed for 1 year.

2) We will give you long time technology supply.

3) We can dispatch our engineer to you for installing and debugging machines. Engineer's roundtrip tickets, accommodation, and your side travelling fee will be charged by you.

4)We can also supply you mounting process, so your engineers can fit and debug machines by themselves.