© 2018 Zhangjiagang Hengyu Machinery Co.,LTD All rights reserved. Designed by iwonder.cn Site Map

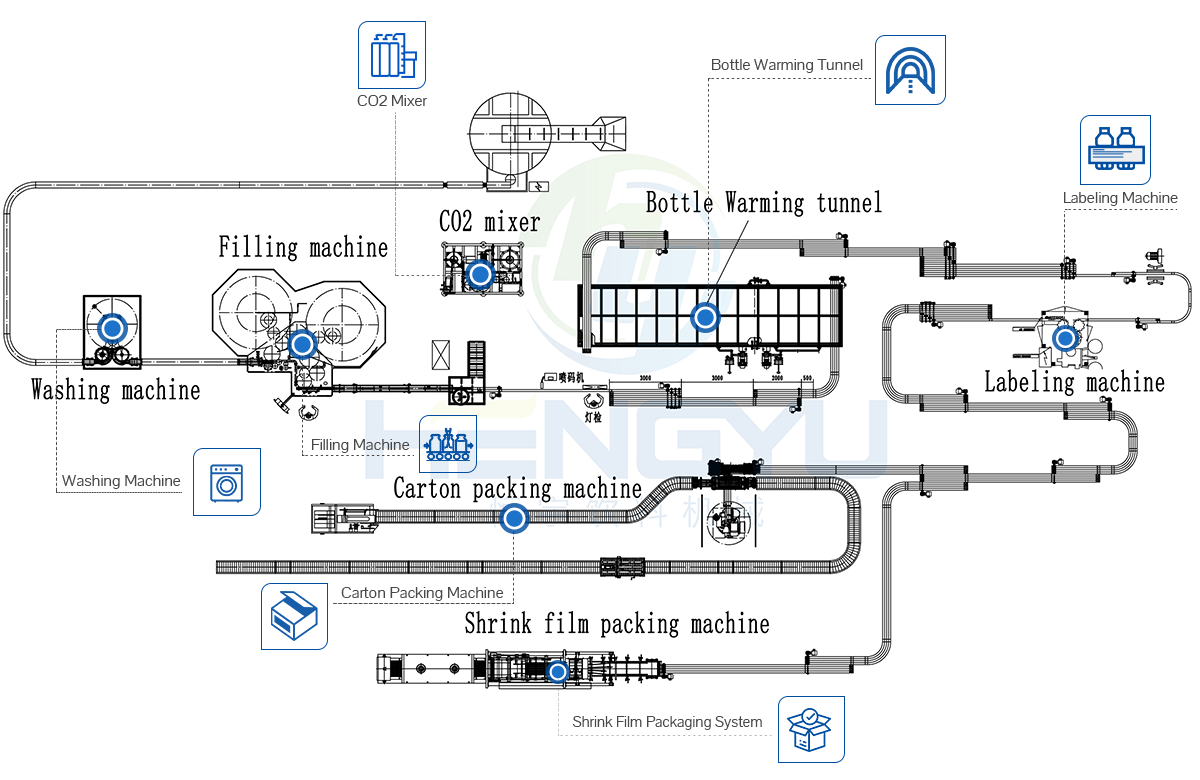

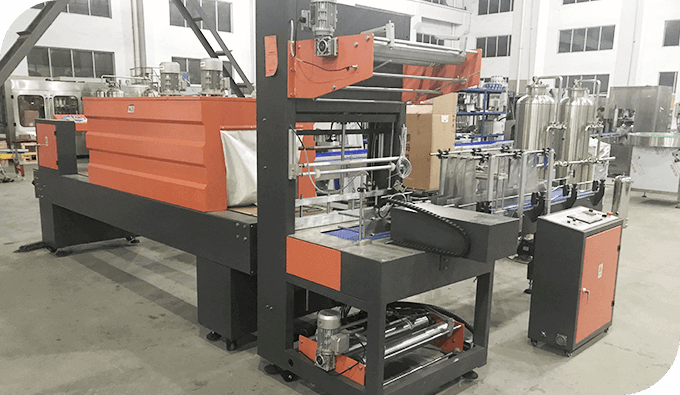

The whole bottled water production line consists of six parts: water treatment, blending system, filling system, sealing system, label system, packaging system and conveying system.

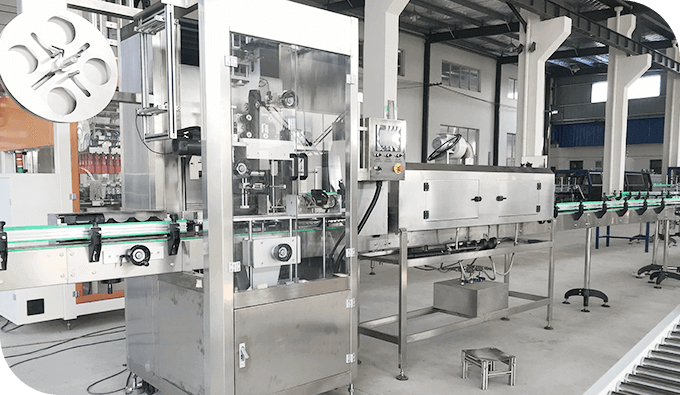

Fully automatic operation mode greatly improves the production efficiency and at the same time liberates the human resources.

The introduction of foreign advanced mixing technology of CO2 and liquid, makes sure the content of the CO2 in the finished product.

Domestic unique sealing technology, wire capping machine, makes us the only supplier of the whole production line for champagne.

With the international electrical brands such as Siemens and Schneider, the operation of the whole line is more stable.

Learn More