© 2018 Zhangjiagang Hengyu Machinery Co.,LTD All rights reserved. Designed by iwonder.cn Site Map

Email: info@hengyu-machinery.com

Email: info@hengyu-machinery.com

Introduction

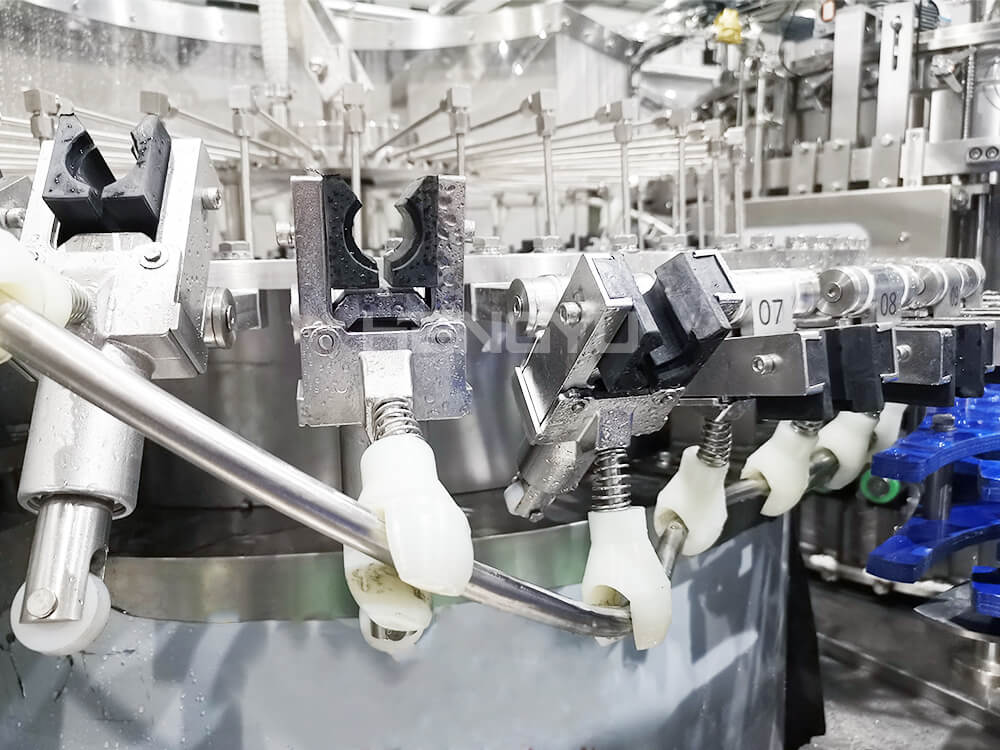

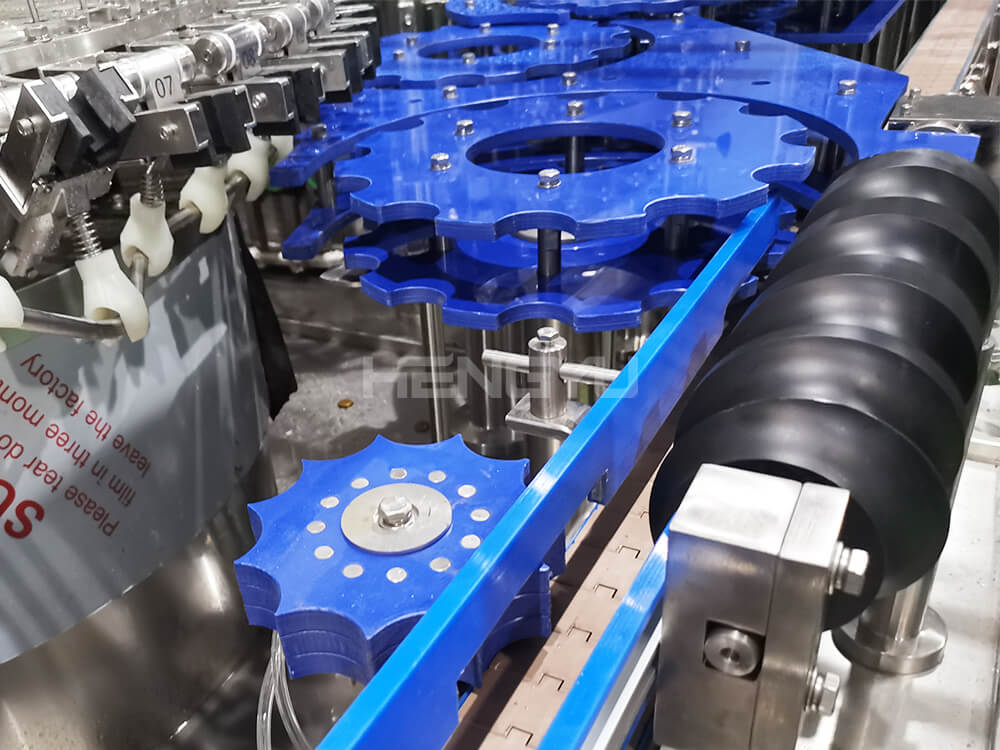

lThe machine adopts high precision mechanical filling valves, has features of no bottle, no vacuuming. lOpening hear combined gear box transmission ,with engaging and disengaging gear device, frequency conversion extends the speed modulation range. lThis machine has self oil lubrication device so than the lubrication points could be lubrication regularly in time. The machine is high efficiency ,low noise and long life. lThe some parts of machine can be adjusted by different size bottle. lThe level is controlled by the electric probe to assure the precise the liquid level.

Technical parameters

Model | 14/12/5 | 18/18/6 | 24/24/8 | 32/32/10 | 40/40/10 | 50/50/12 | 60/60/15 |

Rinsing heads | 14 | 18 | 24 | 32 | 40 | 50 | 60 |

Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 |

Capping heads | 5 | 6 | 8 | 10 | 10 | 12 | 15 |

Capacity | 2000 | 5000 | 7000 | 9000 | 14000 | 18000 | 24000 |

Power(kw) | 2.2 | 3.5 | 4.5 | 6 | 7.5 | 9.5 | 11.2 |

Dimension | 2300*1600 | 2600*1920 | 3100*2200 | 3850*3000 | 4850*3800 | 7570*3550 | 6500*5500 |

Weight(kg) | 2800 | 3650 | 4800 | 6800 | 8650 | 10500 | 12800 |

Performance

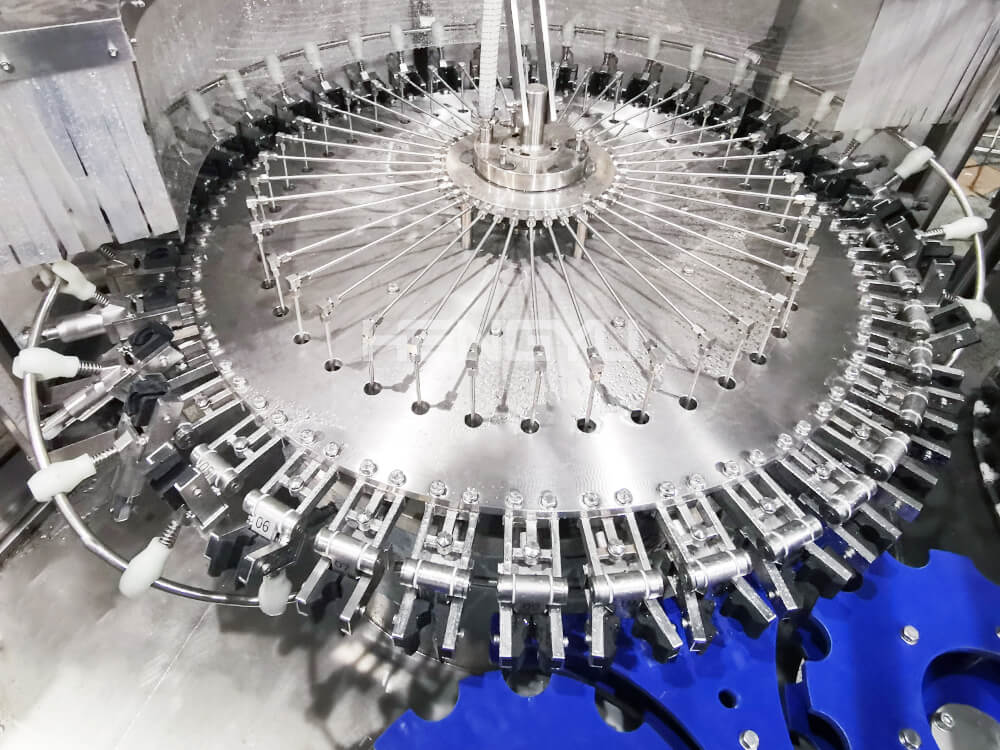

a.This carbonated beverage filling equipment adopts bottle neck holding transmission technology to realize fully automatic rinsing,filling and capping.

b.It is equipped with CO2 accuracy pressure control,so that the liquid level is always stable.

c.The application of alarm devices for bottle jam,bottle shortage.bottle demage,cap shortage,over loading etc,in several places ensure the quality of its production.

d.The machine obtains advantages of high reliability ,high efficiency, high grade of automation and easy operation,etc.

The whole production line for the carbonated PET bottle:

-Water Treatment System

1 Raw water tank + Raw water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

1/Stainless steel high pressure film shell

2/All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3/Online type pressure auto self-protection device

4/Online type electricity indicator (with stable compensation)

5/System safe protecting and alarm system

6/System frame

-Bottle Blowing Part

1)Widely used to produce the carbonated bottle,mineral water bottle,pesticide bottle,oil bottle and cosmetics etc.

2)Suitable for producing PET plastic containers and bottles in all shapes.

3)With famous electrical components and have various capacities.

-Carbonated Drink PET Bottle Washing Filling Capping 3 in 1 machine

The machine is advanced filling and capping equipment, it’s designed on the basis of absorbing domestic and foreign advanced technology. It is mainly used in filling and capping carbonated beverages like soft drinks, cola, sparkling wine, etc. It has such

advantages as advanced construction, stable working, convenient operation, and repair & maintenance, transducer control as well as high production efficiency. It is the ideal equipment for mid-scale & small-scale beverage factory.

-Carbonated Beverage Mixer

suitable beverage types: Cola and lemon.

2. mixing ratio range: 3:1 - 6:1

3. CO2 content: 4 times

4. volume: CO2 consumption of about 4 M3/h

5. CO2 supply pressure: 0.8-1 Mpa

6. CO2 Purity: 99.9%

7. consumption of ethylene glycol solution: water=30M3/h

8. ethylene glycol solution pressure: 1.0Mpa

9. ethylene glycol solution inlet temperature: -2 C

-The Sleeve Labeling Machine.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

-Packaging Part

1)PE film shrink wrapping machine

2)Half-tray shrink wrapping machine

3)Carton box packaging machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product

Our company

Zhangjiagang Hengyu Machinery Co., LTD is located in Zhangjiagang city, a typical civilized city in China, where we west to SHANGHAI, east of NANJING and on the south bank of Yantze River. The transportation is very convenient.

Based on the technical achievement and producing experience, we learn and digest the advantages of domestic and foreign friends, introduce the newest beverage packaging machinery technology from Germany and Italy to Form your own competitive

The company has also obtained a variety of certification so that customers can buy at ease and use at ease.

What Zhangjiagang Hengyu Beverage Machinery company can do for you ?

1)The machines' quality that we sold will be guaranteed for 1 year.

2) We will give you long time technology supply.

3) We can dispatch our engineer to you for installing and debugging machines. Engineer's roundtrip tickets, accommodation, and your side travelling fee will be charged by you.

4)We can also supply you mounting process, so your engineers can fit and debug machines by themselves.

We focus on customer satisfaction

Always by your side on every step of the way to build, maintain and improve your line performance

HENGYU SERVICE ONLINE.

It is a user-friendly interface, available 24/7, in 9 languages, and is your one-stop online shopping. Designed to make your life easier in your day to day business, it will help you to improve your line and maintain its performance.

OPTIONS & UPGRADES.

Since we built your line, we have a comprehensive understanding of its design, and our engineering experts can analyze equipment and processes to determine how to strengthen performance. As new technologies and solutions are introduced to the market, we ensure that your production benefits accordingly, so you can stay on target in a changing, competitive marketplace.

SPARE PARTS.

When it comes to your production, speed is of the essence and every second of uptime saves you money. That's why you need the best quality parts, delivered in full and on-time - parts that work as quickly as possible, for as long as possible. As an original equipment manufacturer with an installed base of over 30,000 machines, we can deliver on your every spare part need.

Comprehensive Solutions

Initial Evaluation.

Evaluate the project from feasibility, scale and market positioning.

Parameter Design.

Analyze and design the technical parameter of your engineering project.

Proposal Confirmation.

Confirm the project implement a proposal from your general instance.

Project Execution.

According to the project plan, complete the manufacture and installation of machines, until passing the final trial.

Personal Training.

Improve the technical level of operators as well as operative skills of the equipment.

Service After-sales.

Customer-centered service: offer rapid effective engineering service.

Processing Center

HENGYU has several state-of-the-art CNC machining centers and lathes which make sure every processed part meets the design requirements in order to guarantee the stability, reliability, and durability of every equipment and machine.

Best Suppliers

HENGYU not only upgrades the research and development of technology, the precision of process, the assembling level and the detection methods but also integrates the best suppliers. All the components from Huihe are provided by well-known brands at home and abroad.

Packing & Delivery

Package Type : As usual, we adopt wooden case as package type. It's suitable for long-distance transport. According to customers' special demand, we could adopt sheet iron case and so on.

Transport : By sea. By train. By aircraft.