© 2018 Zhangjiagang Hengyu Machinery Co.,LTD All rights reserved. Designed by iwonder.cn Site Map

Email: info@hengyu-machinery.com

Email: info@hengyu-machinery.com

Introduction

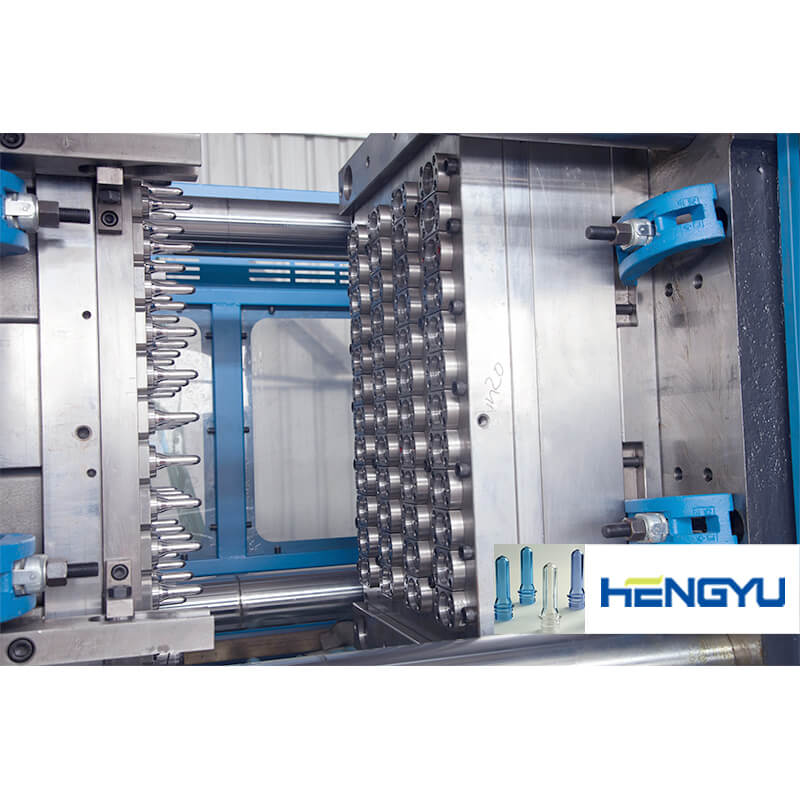

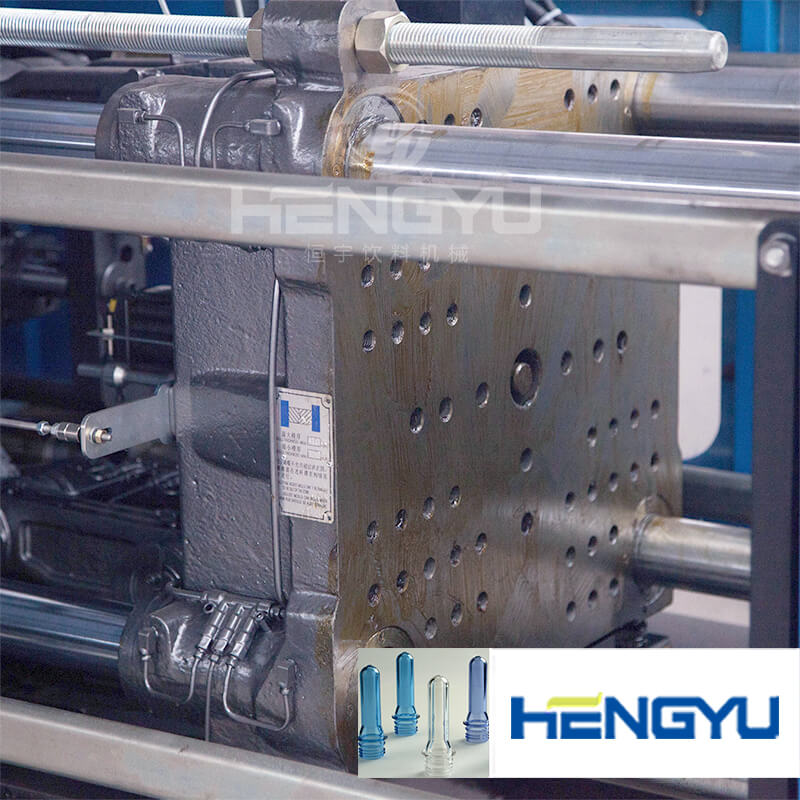

1. Big diameter screw design and L/D ratio.

2. High plasticization capacity.

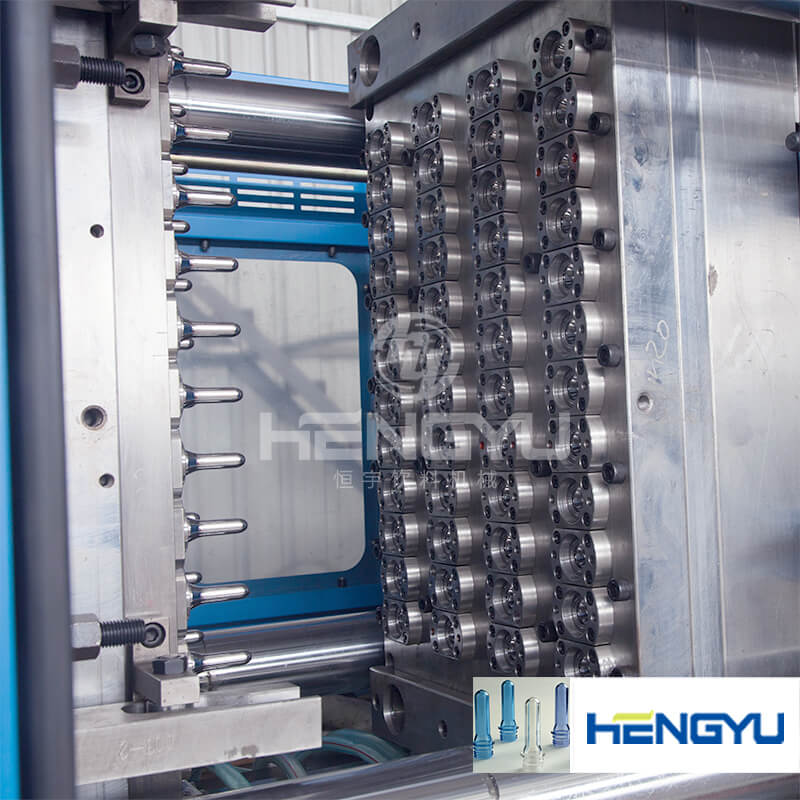

3. Extended machine framework, enlarged space between tie bars, mold opening stroke, mold thickness, and ejection stroke.

4. Specialized screw set for PET + FB or slice PET are on request as option.

5. Four or above stages precise temperature PID control for barrel.

6. Spring nozzle for the machine blow 650T, hydraulic nozzle for 650T, and meeting customers' special requirements by effectively avoiding overflow.

7. Dehumidifying dryer selected for PET resin's special demands of removing moisture.

8. Suitable for both varied pump and standard pump.

KM PET Drinking Water Bottle Blowing Machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Technical parameters

Item | Model | Capacity Per hour | Volume | Cavity | Neck Size |

1 | KM-A1 | 800-1200bph | 0.1-2L | 1 | ≤30 |

2 | KM-A2 | 500-800bph | 0.1-5L | 1 | ≤45mm |

3 | KM-B2 | 800-1000bph | 0.1-5L | 2 | 40-45mm |

5 | KM-C3 | 1800-2500bph | 0.1-1.5L | 3 | 28mm-30mm |

6 | KM-A2 | 1800-2000bph | 0.1-2L | 2 | ≤38mm |

7 | KM-A4 | 3200-4000bph | 0.1-2L | 4 | ≤38mm |

8 | KM-A6 | 4000-5500bph | 0.1-1.5L | 6 | 28-30mm |

9 | KM-A8 | 6000-7000bph | 0.1-1.5L | 8 | 28-30mm |

Functions

1.The design of equipment is logical, easily operation.

2.The automatic level is very high, the wage is very little.

3.Using famous imported hydraulic, electrical, sealing parts, the trouble is low.

4.No matter what the product’s outside or inside, they can get the best guarantee, the good products rate can be above 99%

1) LCD computer control with big display screen

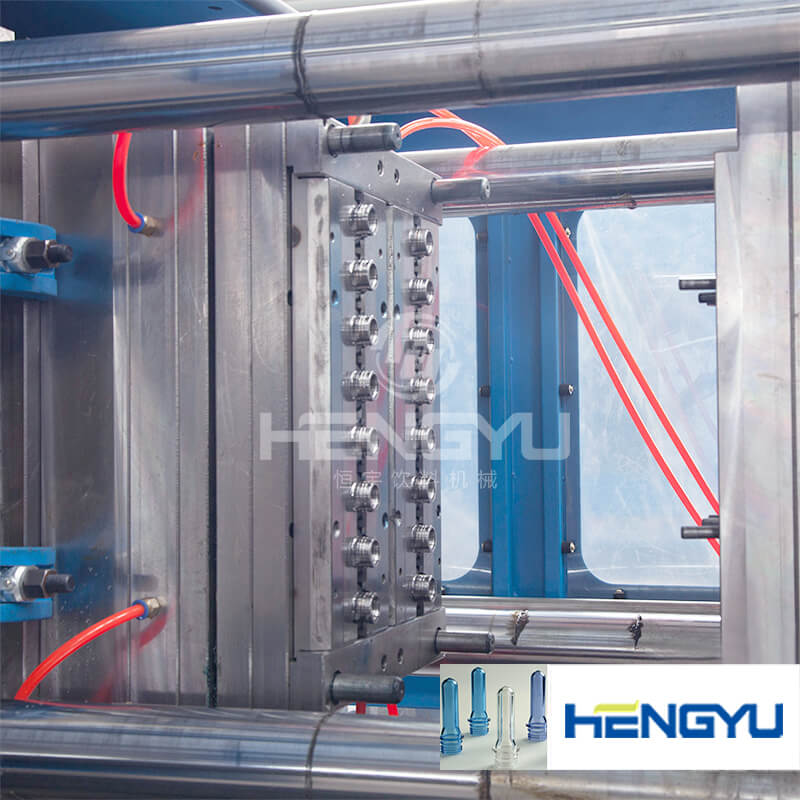

2) Hydraulic double proportional valve

3) Hard chrome plated high tensile strength steel tie bars

4) Generous space for fitting large moulds

5) Large opening stroke

6) Two position transducers to control Clamping and Injection

7) Four stages of injecting, independent velocity and pressure control

8) Hydraulic mould height adjustment device

9) Screw cold-start prevention device

10) Melt decompression control

11) Screw back pressure control

12) Multiple hydraulic ejection

13) Differential high speed clamping

14) Centralized lubrication system

15) Low pressure mould protection device

16) Mechanical safety interlock

17) Double electrical safety interlock

18) Oil return filter

19) Oil tank with inner stainless steel container

Technical parameters

NO. | Parts Name | Brand | Origin |

1 | Hydraulic Motor | DAN DUN | Italy-China |

2 | Hydraulic Oil Pump | HIGH-TECH | Made in Taiwan |

3 | Proportional Hydraulic Valve | HUAYE | Made in China |

4 | Transducer | Gefran

| Made in Italy |

5 | Sealing Rings | HALLITE | Made in USA |

6 | Reversal Hydraulic Valve | SUNNY | Made in USA |

7 | High-pressure Vitta | Barthez | Made in Portugal

|

8 | Contactor | LG | Made in Korea |

9 | Air-break Switch | LG | Made in Korea |

10 | Computer | TECHMATION | Made in Taiwan |

11 | Limit Switch | OMRON | Made in China |

12 | Proximity Switch | SCHNEIDER | Made in China |

Company information

Companies to many years of research results and production experience as the basis, widely absorb and digest the advantages of the same industry at home and abroad, and one after another from

Germany, Italy, the introduction of a full set of the latest beverage packaging machinery technology. To Provide high quality beverage equipment for domestic and international customers. The company

has several series of independent research and development products, has obtained the national patent. As the senior beverage machine manufacturer, the working environment is elegant, has the per-fact

modern office condition, has the specialized sales department, the research and development department, the technical department.

Packing & Delivery

Package Type : As usual, we adopt wooden case as package type. It's suitable for long-distance transport. According to customers' special demand, we could adopt sheet iron case and so on.

Transport : By sea. By train. By aircraft.

Our services

1)The machines' quality that we sold will be guaranteed for 1 year.

2) We will give you long time technology supply.

3) We can dispatch our engineer to you for installing and debugging machines. Engineer's roundtrip tickets, accommodation, and your side travelling fee will be charged by you.

4)We can also supply you mounting process, so your engineers can fit and debug machines by themselves.