© 2018 Zhangjiagang Hengyu Machinery Co.,LTD All rights reserved. Designed by iwonder.cn Site Map

Email: info@hengyu-machinery.com

Email: info@hengyu-machinery.com

Capacity: 9000BPH

Material: SUS340/316

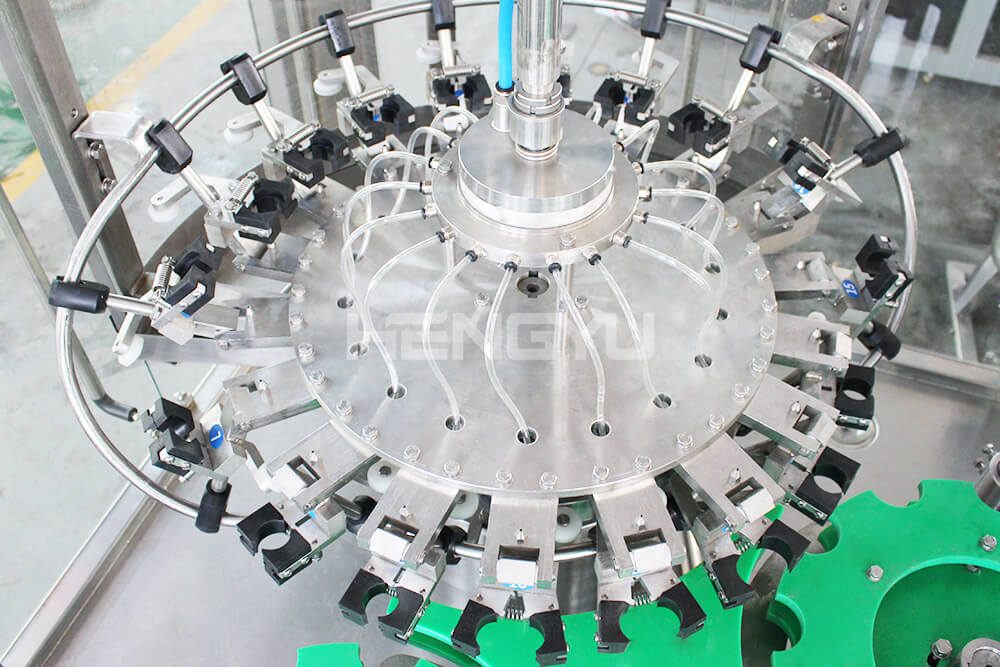

Function: Filling and sealing

Introudction

1.This production line is mainly used in washing, filling and capping for pop cans made of two cans, aluminium alloy or PET plastic cans.

2. It has automatically raised battlements cans,auto turn over, automatic washing filling and capping functions.

3. The production capacity is high. It is the best equipment for the production of carbonated beverage for cans.

The machine is mainly used in the juice and non-carbonated beverages filling operations. The three funtions of bottle washing,beverages filling and capping are intergrated in one machine. The whole process is automatic. The machine is used to fill fruit juice,tea or energy drinks made of PET or glass. It also can be used to fill mineral water and purified water. The machine is conveniently adjustable to fill various type of bottles. The filling operation is faster and more stable due to the micro-negative pressure filling operation of the new type is adopted. The output and benefit of the machine is higher than the machines of the same specifications. The advanced OMRON programmable logic controller(PLC) is adopted to control the machine to run automatically. Air conveyor system is adopted in bottle entry section and belt conveyor system is adopted in bottle exit section,which can adjust speed and coordinate with transducer of the main inspected to run with photo electrical detector. The machine is an ideal-preferred equipment for beverage manufacturers.

Application

This juice filling 3-in-1 machine is washing ,filling and capping 3 in 1,used for PET fruit juice ,tea drinks and other heating filling production lines. It is designed by advanced technology that scientific reasonable. It is nice appearance ,complete functions, easy to operate and maintenance ,high automatic .It is the best choice for heating filling products manufacturers.

Characteristic

This machine used advanced MMI automatic control system and variable-frequency speed control system(VWF)

Designed by the structure of suspension type getting stuck the bottleneck and conveying, filling valve lift technology to meet the requirement of heat filling within 95℃

There is constant temperature circulation system, self temperature control and liquid reflux

The machine parts of direct control with liquid like inlet valve used stainless steel SUS301 material. The main motor ,reducer, bearings, sealing elements ,electrical apparatus elements and pneumatic elements are all imported form well-known manufacturers of the world

Techinical parameter

| Model (RCGF) | 14/12/5 | 18/18/6 | 24/24/6 | 32/32/8 | 40/40/10 | 50/50/12 | 60/60/15 |

| Rinsing heads | 14 | 18 | 24 | 32 | 40 | 50 | 60 |

| Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 |

| Capping heads | 5 | 6 | 6 | 8 | 10 | 12 | 15 |

| Capacity (BPH) | 3000 | 5000 | 8000 | 12000 | 15000 | 18000 | 25000 |

| Power(kw) | 2.2 | 3.5 | 4.5 | 6 | 7.5 | 9.5 | 11.2 |

| Dimension (mm) | 2300*1600 *2500 | 2600*1920 *2550 | 3100*2100 *2800 | 3850*3000 *2850 | 4850*3800 *2750 | 5750*3550 *2750 | 6500*5500 *2750 |

| Weight(kg) | 2600 | 3650 | 4800 | 6800 | 8500 | 10000 | 12000 |

Our company

Zhangjiagang Hengyu Beverage Machinery CO., Ltd is a professional manufacturer of Food and Beverage production line equipments, which integrate design and manufacture, installation and debugging, manning guide, after-sales service.

Based on the technical achievement and producing experience,we learn and digest the advantages of domestic and foreign friends,introduce the newest beverage packaging machinery technology from Germany and Italy to Form your own competitive advantage.

Our equipment products are applied to multiple beverage fields such as carbonated beverage,fruit juice,dairy drinks,pure water,spring water,grape,liquor, sparkling wine,seasoning,pureed drinks and oils.We can offer the whole water treatment system and automatic barreled water production line.The range of equipment we can produce covers the whole production line from pretreatment to filling and packaging system.Meanwhile,to fit some custom-made request for their different production conditions and capacity requirements,our engineers can also design special beverage machines.

The beverage filling machine of us not only sold throughout our China mainland, but also export to Russia, South Africa, England, Malaysia, Singapore, Burma, Sri Lanka and other dozens of counties.We have created a proud achievement in these years ,received widely by customers and laid a solid position in this beverage machinery field.

The company integrates the enterprise and the factory in one body.Production is connected with sales intelligently to fully guarantee the vital interests of the vast number of customers.

Packing & Delivery

Package Type : As usual, we adopt wooden case as package type. It's suitable for long-distance transport. According to customers' special demand, we could adopt sheet iron case and so on.

Transport : By sea. By train. By aircraft.

Our services

1)The machines' quality that we sold will be guaranteed for 1 year.

2) We will give you long time technology supply.

3) We can dispatch our engineer to you for installing and debugging machines. Engineer's roundtrip tickets, accommodation, and your side travelling fee will be charged by you.

4)We can also supply you mounting process, so your engineers can fit and debug machines by themselves.

FAQ

Q1: How to choose the most suitable machine and get the final suitable price?

A1: For beverage bottle Filling Machine, you need to reply us the following questions:

1. What kind of product (carbonated or no carbonated beverage, juice or water) for filling?

2. What's the volume of the bottle(Can)?

3. Could you show us picture of your Bottle/can?

4. Could you send some bottle samples to us?

5. What capacity do you need for production?

Q2: Do you have videos or manual for us to know the machine better?

A2: Yes, of course. Please email us and ask for it. We will send you soon.

Q3: How about your machine's quality?

A3: Every machine is applied with CE certificate, SGS certificate, highly meets requirement of TUV, made of SUS 304 for food packaging; SUS316 for pharmaceutical products packaging. Inspect certificate is available.

Q4: What's the delivery time?

A4: Depending on your order: for whole production line it is 40~60 workdays. bottle or tube filling machine, labeling machine, capping machine, unscrambling machine, cansealing machine will be 30~40 days. Other simple equipment will be around 20 days. The above delivery time is calculated after receiving the down payment as well as sample bottles / tubes and materials.

Q5: Is there MOQ for your machine?

A5: 1 set is acceptable. Of course, if you order more, it will be fine and its price will be more competitive.

Q6: How to install the machine?

A6: Please do not worry. We will send you detailed video and instruction manual for your reference. Customer also can appoint your engineers to our factory to learn. Our engineers also can go abroad to install the machine well, however, customer needs to pay round air tickets, hotel and service expenses.