© 2018 Zhangjiagang Hengyu Machinery Co.,LTD All rights reserved. Designed by iwonder.cn Site Map

Email: info@hengyu-machinery.com

Email: info@hengyu-machinery.com

Introduction

1 / Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

2 / Production flexibility: PET bottle sizes ranging from 200 ml to2 L, with modular design for future technologies

3 / Optimum uptime: 30 % reduction in changeover and maintenance downtime

4 / Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

5 / Hygiene improvement through volume control and contactless filling

6 / Automatic dummy bottles: Safer, easier cleaning procedures

7 / Automatic bottle changeover improves uptime

Technical parameters

Model | 14/12/5 | 18/18/6 | 24/24/8 | 32/32/10 | 40/40/10 | 50/50/12 | 60/60/15 |

Rinsing heads | 14 | 18 | 24 | 32 | 40 | 50 | 60 |

Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 |

Capping heads | 5 | 6 | 8 | 10 | 10 | 12 | 15 |

Capacity | 2000 | 5000 | 7000 | 9000 | 14000 | 18000 | 24000 |

Power(kw) | 2.2 | 3.5 | 4.5 | 6 | 7.5 | 9.5 | 11.2 |

Dimension | 2300*1600 | 2600*1920 | 3100*2200 | 3850*3000 | 4850*3800 | 7570*3550 | 6500*5500 |

Weight(kg) | 2800 | 3650 | 4800 | 6800 | 8650 | 10500 | 12800 |

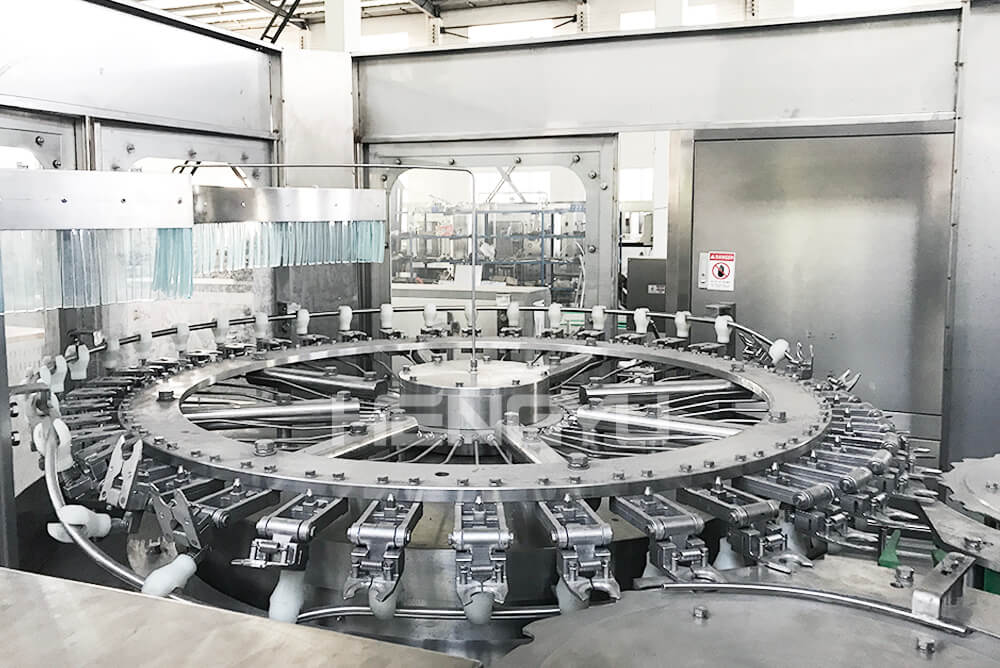

Machine details

Washing heads

1)Into bottle way is air conveyor direct connection with Bottle dial .

2)All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

3)304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

4)304/316 stainless steel washing pump make the machine more durable .

Filling heads

1)304/316 Stainless steel high precision filling nozzle

2) Filling volume adjustable in fine rank, same liquid level after filling

3)All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4) 304/316 stainless steel filling pump

5)Efficient spray nozzle rinse thoroughly and save water for flushing

Capping heads

1) Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

2)All 304/316 stainless steel construction

3)No bottle no capping

4)Automatic stop when lack of bottle

5)Capping effect is stable and reliable ,Defective rate ≤0.2% .

Company information

Companies to many years of research results and production experience as the basis, widely absorb and digest the advantages of the same industry at home and abroad, and one after another from Germany, Italy, the introduction of a full set of the latest beverage packaging machinery technology. To Provide high quality beverage equipment for domestic and international customers. The company has several series of independent research and development products, has obtained the national patent. As the senior beverage machine manufacturer, the working environment is elegant, has the per-fact modern office condition, has the specialized sales department, the research and development department, the technical department.

Our service

1)The machines' quality that we sold will be guaranteed for 1 year.

2) We will give you long time technology supply.

3) We can dispatch our engineer to you for installing and debugging machines. Engineer's roundtrip tickets, accommodation, and your side travelling fee will be charged by you.

4)We can also supply you mounting process, so your engineers can fit and debug machines by themselves.

Packing & Delivery

Package Type : As usual, we adopt wooden case as package type. It's suitable for long-distance transport. According to customers' special demand, we could adopt sheet iron case and so on.

Transport : By sea. By train. By aircraft.