© 2018 Zhangjiagang Hengyu Machinery Co.,LTD All rights reserved. Designed by iwonder.cn Site Map

Email: info@hengyu-machinery.com

Email: info@hengyu-machinery.com

INTRODUCTION

Bottle beverage machines are used to fill liquid in cans and seal cans.

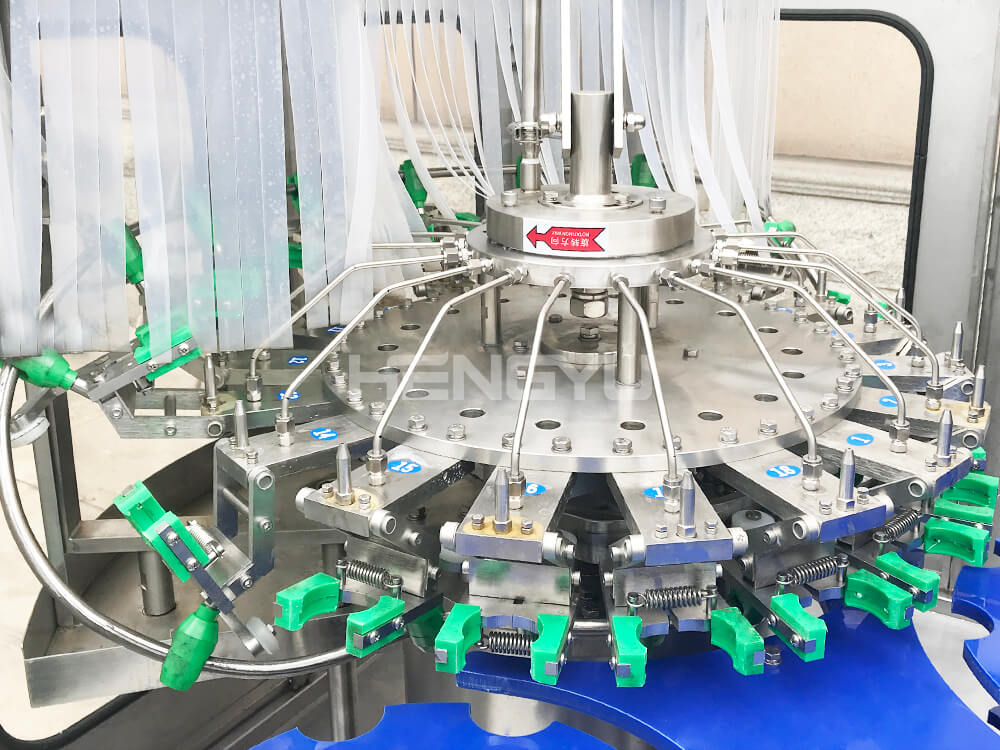

The Liquid can filling, sealing machines were made based on absorbing advance technology from abroad. All the canning machines adopt the advanced mechanical, electrical and pneumatic control technology. Can filling and seaming system were made in one unit. The filling system driving force was supplied by seaming system to assure the synchronization. With using counter pressure filling principle, filling work is stable, fast, accurate and has no leakage. Capping performance is well. The can filling machine owns stable working, elegant appearance, easy maintainence, motor speed frequency control. It also can be equipped with long-range control system according to customers’ requirement. It is the ideal machine for beer and beverage factory.

We are specialized in manufacturig can filling machine from China.

PERFORMANCE

a.This carbonated beverage filling equipment adopts bottle neck holding transmission technology to realize fully automatic rinsing,filling and capping.

b.It is equipped with CO2 accuracy pressure control,so that the liquid level is always stable.

c.The application of alarm devices for bottle jam,bottle shortage.bottle demage,cap shortage,over loading etc,in several places ensure the quality of its production.

d.The machine obtains advantages of high reliability ,high efficiency, high grade of automation and easy operation,etc.

TECHNICAL DATAS

Model | 14/12/5 | 18/18/6 | 24/24/8 | 32/32/10 | 40/40/10 | 50/50/12 | 60/60/15 |

Rinsing heads | 14 | 18 | 24 | 32 | 40 | 50 | 60 |

Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 |

Capping heads | 5 | 6 | 8 | 10 | 10 | 12 | 15 |

Capacity | 2000 | 5000 | 7000 | 9000 | 14000 | 18000 | 24000 |

Power(kw) | 2.2 | 3.5 | 4.5 | 6 | 7.5 | 9.5 | 11.2 |

Dimension | 2300*1600 | 2600*1920 | 3100*2200 | 3850*3000 | 4850*3800 | 7570*3550 | 6500*5500 |

Weight(kg) | 2800 | 3650 | 4800 | 6800 | 8650 | 10500 | 12800 |

ADVANTAGES

It has such

advantages as advanced construction, stable working, convenient operation, and repair & maintenance,

transducer control as well as high production efficiency. It is the ideal equipment for mid-scale & small-scale beverage factory.

COMPANY INFORMATION

Companies to many years of research results and production experience as the basis, widely absorb and digest the advantages of the same industry at home and abroad, and one after another from Germany, Italy, the introduction of a full set of the latest beverage packaging machinery technology. To Provide high quality beverage equipment for domestic and international customers. The company has several series of independent research and development products, has obtained the national patent. As the senior beverage machine manufacturer, the working environment is elegant, has the per-fact modern office condition, has the specialized sales department, the research and development department, the technical department.

WHAT ZHANGJIAGANG HENGYU BEVERAGE MACHINERY COMPANY CAN DO FOR YOU ?

1. Installation & adjustment

After the equipment are arrived at the customer's site, the customer is responsible for unpacking and arranging the equipment according to the placement drawing; and does under our install-adjust technicians' guidance. Costs of the staff are decided at last.

2. Training

1). We are responsible for offering the technical training to user. The training content includes the structure and maintenance of the equipment, control and operation of the equipment. Through training, users' technical staff can grasp and the skill of operation and maintenance proficiently, and deal with the general troubles in time. We will appoint qualified technical staff for the guidance.

2). The buyer can send staff to our company for learning.

3. Quality assurance

1). We guarantee the goods offered are brand-new, not used, with latest design and suitable material made, and we guarantee the specification of the equipment is consonance with the contract.

2). We guarantee the line achieve product technical performance indicators within 5 days after feeding operation through the correct guidance of the installation and commissioning.

3). We are responsible for the fault and damage of the production line caused by our design, technology, manufacture, installation, adjustment and material defect etc. that all belong to our responsibility.

4). The warranty period is 12 months after acceptance check of the production line. If there is any different between the furnished equipment in the customer's factory and the equipment concerned in the contract, the users have the right to pass the inspection book to the legal department to claim for compensation to our company within goods warranty period.

4. Warranty

Offer 12 months maintenance period to the problem that caused by our design, manufacture and the material quality, and offer the relevant parts and effective service for free for above reason. We will offer a widely and favorable technical support, after service all the time after guarantee period.

PACKING & DELIVERY

1)The machines' quality that we sold will be guaranteed for 1 year.

2) We will give you long time technology supply.

3) We can dispatch our engineer to you for installing and debugging machines. Engineer's roundtrip tickets, accommodation, and your side travelling fee will be charged by you.

4)We can also supply you mounting process, so your engineers can fit and debug machines by themselves.