© 2018 Zhangjiagang Hengyu Machinery Co.,LTD All rights reserved. Designed by iwonder.cn Site Map

Email: info@hengyu-machinery.com

Email: info@hengyu-machinery.com

CGF 24-24-8 washing filling capping 3 in 1

Capacity is 11000BPH

Touch screen +PLC

Introduction

user:

This CGF Wash-filling-capping 3-in-1unit:Beverage Machinery is used to produce polyester bottled mineral water, purified water, alcoholic beverage machinery and other non-gas beverage machinery. The CGF Wash-filling-capping 3-in-1unit:Beverage Machinery can finish all the process such as press bottle, filling and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency.

Technnical parameters

According to customers' special demand, we could adopt sheet iron case and so on.

Model(CGF) | 14/12/5 | 18/18/6 | 24/24/8 | 32/32/10 | 40/40/12 | 50/50/12 | 60/60/15 |

Rinsing heads | 14 | 18 | 24 | 32 | 40 | 50 | 60 |

Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 |

Capping heads | 5 | 6 | 8 | 10 | 12 | 12 | 15 |

Capacity(BPH) | 4000 | 7000 | 11000 | 13000 | 18000 | 24000 | 28000 |

Power(kw) | 2.2 | 3.5 | 4.5 | 6 | 7.5 | 9.5 | 11.2 |

Dimension(mm) | 2400*1650*2500 | 2600*1920*2550 | 3100*2100*2800 | 3800*2800*2900 | 4600*2800*2900 | 5450*3300*2900 | 6500*4500*2900 |

Weight(kg) | 2500 | 3500 | 4500 | 5600 | 8500 | 9800 | 12800 |

Characteristic

1)The water bottle filling machine is mainly used for PET bottled non-carbonated beverage production line,such as spring water and wine drinks.

2)Washing,filling and capping are available in one machine.

3)The contact time between raw materials and the outside world has been reduced to improve the health conditions, production capacity and economic benefits.

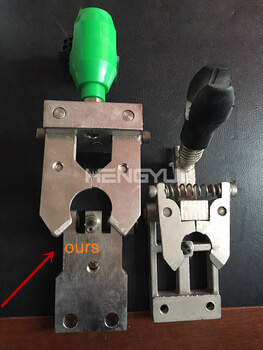

4)The structure of conveying is hanging type and clamping the bottleneck to easily change bottle type.

5)Using the advanced PLC(Programmable Logic Controller) technology.

6)The major electrical apparatus are all products of well-known brands, such as SIEMENS, MITSUBISHI, Schneider and OMRON.

Package & Delivery

Package Type : As usual, we adopt wooden case as package type. It's suitable for long-distance transport.

According to customers' special demand, we could adopt sheet iron case and so on.

Transport : By sea. By train. By aircraft.

Company information

Companies to many years of research results and production experience as the basis, widely absorb and digest the advantages of the same industry at home and abroad, and one after another from Germany, Italy, the introduction of a full set of the latest beverage packaging machinery technology. To Provide high quality beverage equipment for domestic and international customers. The company has several series of independent research and development products, has obtained the national patent. As the senior beverage machine manufacturer, the working environment is elegant, has the per-fact modern office condition, has the specialized sales department, the research and development department, the technical department.

Our serivices

1)The machines' quality that we sold will be guaranteed for 1 year.

2) We will give you long time technology supply.

3) We can dispatch our engineer to you for installing and debugging machines. Engineer's roundtrip tickets, accommodation, and your side travelling fee will be charged by you.

4)We can also supply you mounting process, so your engineers can fit and debug machines by themselves.