© 2018 Zhangjiagang Hengyu Machinery Co.,LTD All rights reserved. Designed by iwonder.cn Site Map

Email: info@hengyu-machinery.com

Email: info@hengyu-machinery.com

Introduction

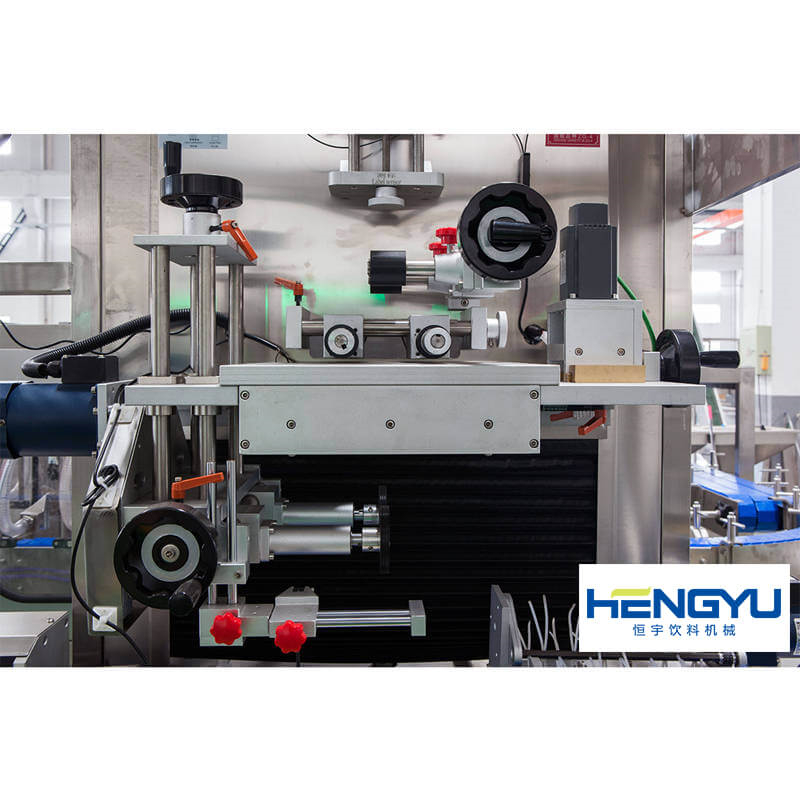

1. Covering the circle label on the pet bottle and then hot shrinking to fix on the position which bottle body designated.

2. The machine's structure is compact and suitable for the production line of different direction and different height.

3. It is controlled by micro-computer to realize automatic detection and positioning.

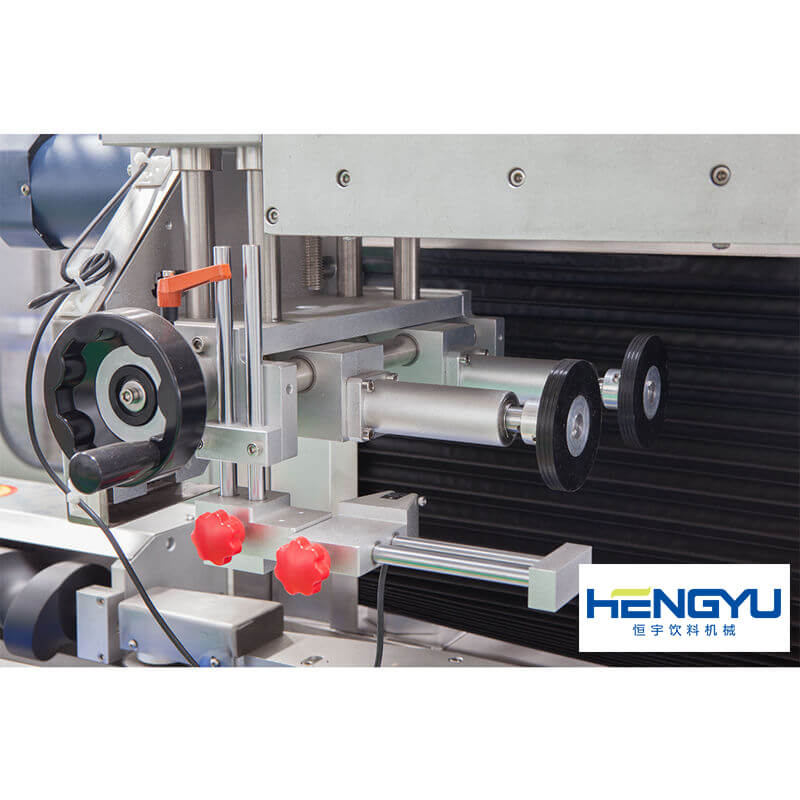

4. The machinery part adopts combination designing of modularization,and makes the machine reasonable.

5. The height adjustment adopts motor fluctuating, it is convenient to replace the material. The special cutter head designing make the film-rolling cut more exactly.

Technical parameter

Technical Parameter | |

Model | HY-TBJ-150B |

HY-TBJ-250B | |

Capacity | (on the base label length :500ml) |

3000BPH-6000BPH | |

6000BPH-10000BPH | |

Label size | Diameter 50-110mm |

Diameter 30-125mm | |

Bottle heights | Heights 50-200mm |

Bottle diameter | Diameter 40-120mm |

Diameter 28-125mm | |

Label sleeve length | 40-150mm |

30-250mm | |

Thickness | > 0.035mm |

> 0.035mm | |

Label material | PVC/ PET |

PVC/ PET | |

Electrical power | 2.5KW (380V 50HZ) |

Overall diameter | 2440*890*2200mm |

Weight | Approximate 750KG |

Approximate 950KG | |

Characteristic

This machine adopts international advanced technology;cover the circle label on the PET bottle.And then hot shrinking to fix on the position which bottle body designated.

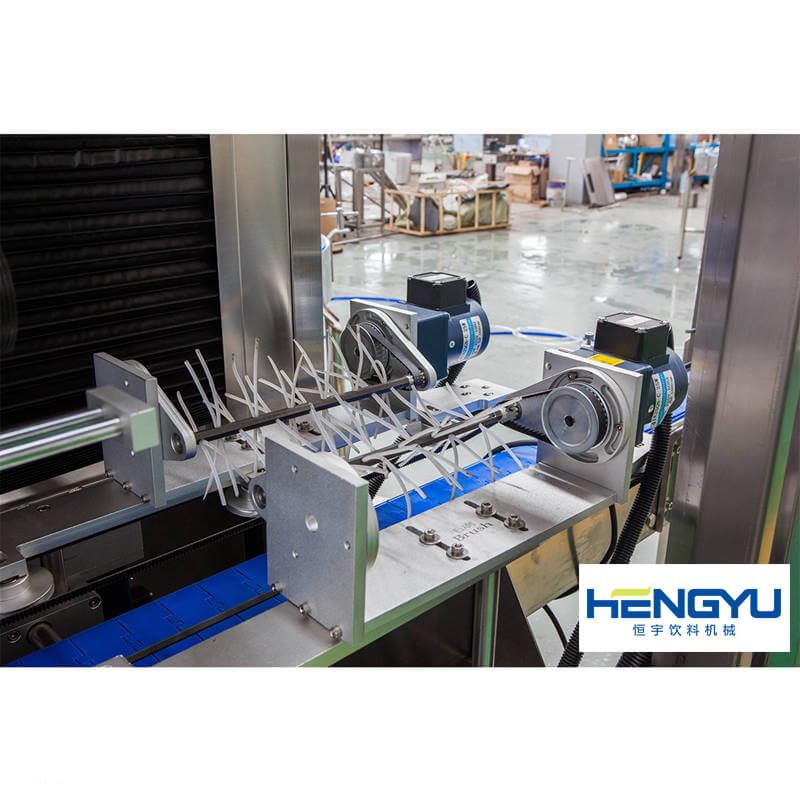

The machinery part adopts combination designing of modularization,and makes the machine reasonable.The height adjustment adopts motor fluctuating;it is convenient replace the material.The special cutter head designing,

make the film-rolling cut more exactly and reliably.

The match machine and labels:

Steam generator for shrink sleeve labeling machine

The water is fed into the series of wholly automatic electrical heating generator by high pressure potential vortex pump made of copper with short water-supply time and durable service. A floating ball for liquid level is fixed in the water tank to automatically control the water inlet. Working system is all automatically controlled. After connecting the water supply and power supply for 5 minutes or so, it can output the steam continuously with a high level of working efficiency.

Different Labels for Different Labeling Machine

1/PVC/PET shrink film label.

Widely used in food, beverages, mineral water and daily products.

Material: PVC heat shrinkable film, PET heat shrinkable film.

PVC shrinkage: longitudinal shrinkage 1%-4%, transverse shrinkage 55%;

PET shrinkage: longitudinal shrinkage 1% -3%, transverse contraction 70%;

PVC/PET heat-shrinkable labels printed flattened folding diameter: not more than 270mm;

Height: according to customer requirements;

Thickness: 3 wire to 5.5 wire, according to customer requirements, roll or cut sheet can be;

Color: Up to 9 colors

2/Sticker label.

Material: Coated paper, Synthetic paper, BOPP.

Color: Up to 9 colors.

3/OPP label.

Material: PVC heat shrinkable film PET heat shrinkable film;

PVC shrinkage: longitudinal shrinkage 1%-4% lateral shrinkage 55%;

PET shrinkage: longitudinal shrinkage 1%-3% lateral shrinkage 70%

Company information

Companies to many years of research results and production experience as the basis, widely absorb and digest the advantages of the same industry at home and abroad, and one after another from Germany, Italy, the introduction of

a full set of the latest beverage packaging machinery technology. To Provide high quality beverage equipment for domestic and international customers. The company has several series of independent research and development

products, has obtained the national patent. As the senior beverage machine manufacturer, the working environment is elegant, has the per-fact modern office condition, has the specialized sales department, the research and

development department, the technical department.

Our services

1)The machines' quality that we sold will be guaranteed for 1 year.

2) We will give you long time technology supply.

3) We can dispatch our engineer to you for installing and debugging machines. Engineer's roundtrip tickets, accommodation, and your side travelling fee will be charged by you.

4)We can also supply you mounting process, so your engineers can fit and debug machines by themselves.